Focus: Sustainable Hygiene Products Packaging | Period: Winter Semester 2019/2020 | Mentor: Prof. Detlef RheinLaminar is a Reusable Toothpaste Tube that can be infinitely refilled with your favourite toothpaste. Bringing toothpaste packaging higher on the sustainability hierarchy while also making it more accessible.

Context

Over a billion plastic toothpaste tubes are thrown each year, many of them reaching their way into the ocean. Some companies are setting goals to use recyclable plastic by 2025, but there is no guarantee any of it will be recycled; hence why toothpaste tubes must get higher on the sustainability hierarchy and become reusable.

Design Overview

The tube consists of four pieces, a moulded and pressed glass tube, a machine-milled aluminium plunger and cap, and an injection-moulded rubber top for the plunger. All of which are both fluoride and dishwasher-safe. The three holes in the plunger not only cut down on material and weight but also accommodate smaller hands and different grips. Clear tubes and frosted tubes are both available with either a standard plunger or a foldable plunger aimed at travellers.

Ideation

Some of the initial concepts were based on cosmetic and hygiene product packaging. However, after experimenting, it was quickly evident that the viscosity and volume of toothpaste won't work with alternative designs such as the airless pump traditionally used for soap and lotion.

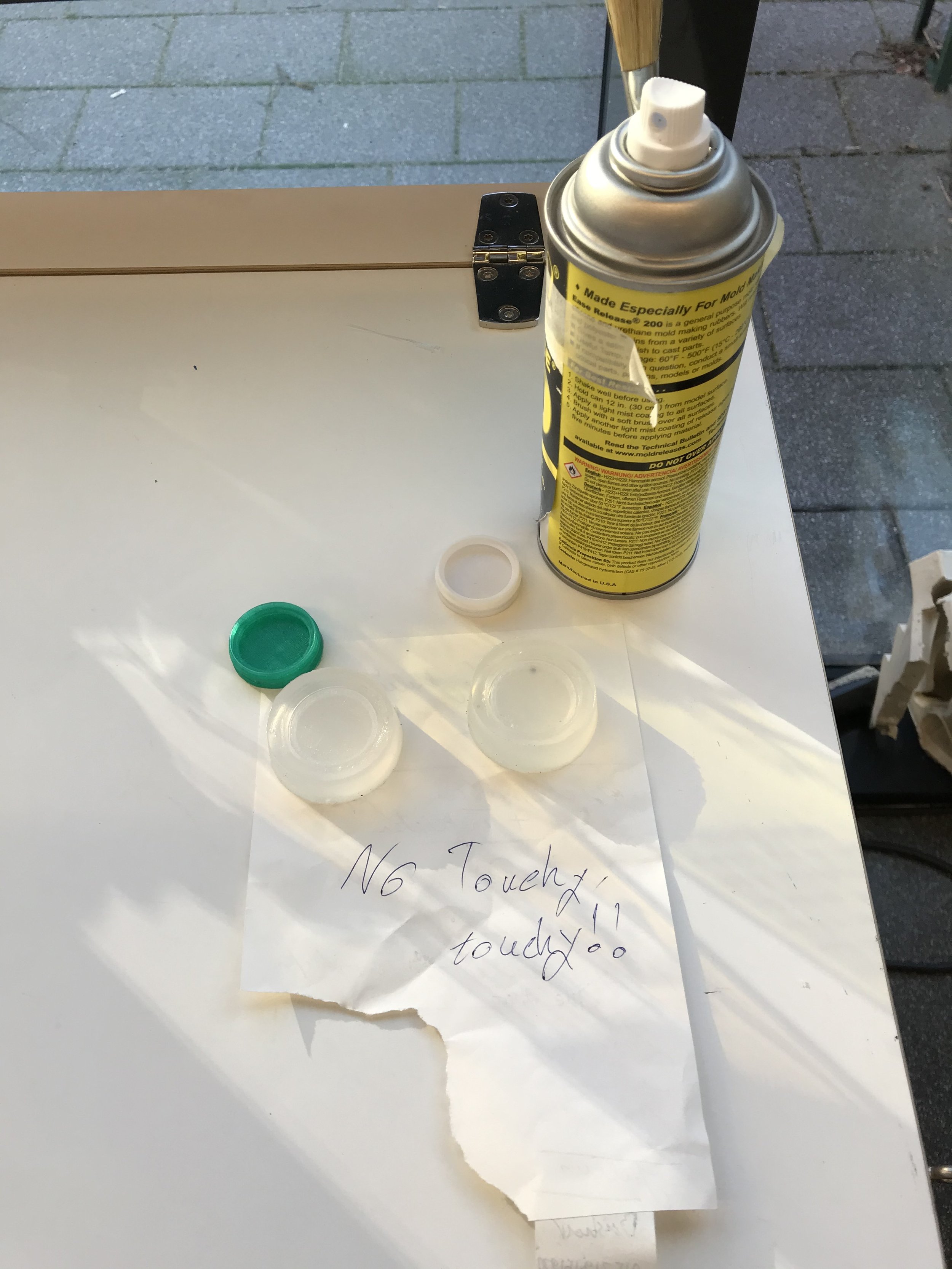

Prototyping

Prototyping custom glass tubes was the hardest challenge. Pressing glass tubes was possible, but only if ordered in large quantities. Glass blowing the tubes was not possible due to intricate detail, so the prototype had to be made from Plexiglas. Due to limited metal milling tools, the prototype plunger, cap, and nozzle were made of carbon fibre 3D prints. Consulting factories have influenced some of the design decisions, further ensuring the possibility of mass production.

Unexpected Inspiration

Throughout the development of the prototype, I kept looking for a way to make the plunger foldable. The idea was to make Laminar easily fit inside small hygiene bags while travelling. After many failed iterations, I finally noticed the cable chain carriers on the 3D printers, the perfect inspiration for a foldable plunger.

Accessibility

The three holes on the plunger are designed to accommodate different grips and smaller hands. However, it was integral to expand the accessibility aspect to accommodate weaker grips, such as individuals with Contracture Deformity of their hands and the elderly.

Prototype Materials

The production challenges mentioned above heavily influenced the final choice of the prototype's materials. As you can see, the original decision of materials, glass and aluminium had to be abandoned for their 3D-printed counterparts.